Solid lubricants

Solid or dry lubricants are substances that can reduce friction between surfaces without requiring a liquid medium.

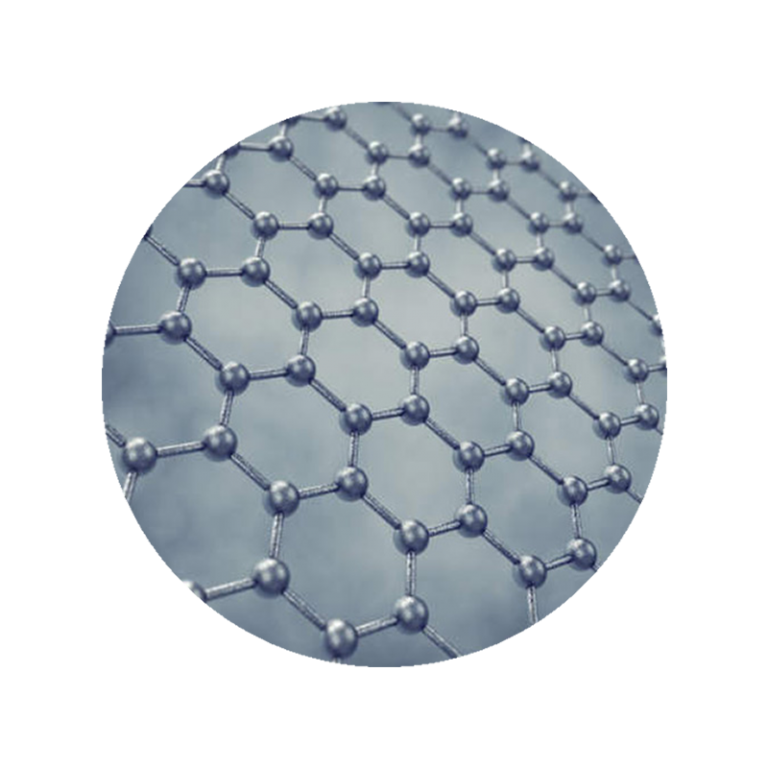

They provide better lubrication at high temperatures than traditional oil-based lubricants, thanks to their layered molecular structure with weak bonding between layers. This allows the layers to slide with minimal force, resulting in lower friction. While a layered crystal structure is often associated with solid lubricants, it is not always a requirement for their effectiveness. In certain applications, substances with non-lamellar structures, like polytetrafluoroethylene (PTFE or Teflon®), are also effective as dry lubricants.

Some of the commonly used solid lubricants include:

• Graphite (C)

• Molybdenum Disulfide (MoS₂)

• Hexagonal Boron Nitride (hBN)

• Polytetrafluoroethylene (PTFE or Cerflon®)

Solid lubricants in oils (dispersions)

Solid lubricants can be dispersed in oils to create a unique combination of lubricants with exceptional properties. While conventional chemical additives can approach some of these properties individually, a perfect blend of colloidal solid lubricants is required to achieve the desired balance of properties in heavy-duty industrial lubricants and high-performance automotive oils and greases.

| Colloidal Solid Lubricant Features | Benefits |

| Reduces friction | Reduced energy costs and improved fuel efficiency, lower running temperatures, improved power output, smooth operation without seizures |

| Increases load capacity | Reduced friction between components during the running-in process, more efficient and effective running-in period |

| Absorbs shocks | Prevents wear caused by vibrations, suitable for heavy-duty conditions, prolonged lifespan of components, reduced maintenance costs |

| Not consumed during operation | Longer drain life |

| Able to operate in dry conditions | Acts as a safeguard against damage or breakdown in case of lubricant supply failure |

Particle size

Controlling particle size is essential in solid/liquid systems as it affects the settling rate of the particles. Smaller particles settle more slowly than larger ones, making it important to control the particle size to maintain the lubricant's performance.

Our colloidal dispersions contains particles that are smaller than blood cells and invisible to the naked eye. This allows them to effortlessly pass through automotive filters without clogging them or causing any build-up.

Stability

Stability is key for any dispersion, regardless of particle size. If a dispersion is unstable, even the finest particles will form clusters and settle. A stabiliser can be added to coat the particles and prevent coagulation.

Our colloidal dispersions contain a carefully designed stabiliser that ensures minimal settling, even during prolonged periods of not being used.

Compatibility

Maintaining stability is crucial for our products to work effectively. Our stabilisers need to work effectively in the dispersion while also maintaining their effectiveness when blended with commonly used lubricants. To guarantee compatibility with all types of oils on the market, we continuously test the stability of our aftermarket additives in combination with the latest engine and transmission oils. These stability tests are carried out under realistic operating conditions, such as high temperatures and moisture contamination, as room temperature stability alone is insufficient.

XENUM applications of colloidal solid lubricants

Ceramic Composite Technology

Ceramic Composite Technology, a concept developed by Xenum, involves the dispersion of ceramic particles or hexagonal Boron Nitride (hBN) in ester oil. This combination provides exceptional lubrication properties, resulting in products that are unrivalled in terms of performance. The polar properties of the ester oils improve lubrication by creating a robust oil film, while also preventing the micro hBN particles from settling.

Ceramic composite additives are used in our VRX 500 and Ceramic oils to spectacularly reduce friction and wear. This results in enhanced power, lower fuel consumption, less pollution, fewer CO2 emissions and less wear. This technology is perfect for high-performance and racing applications as well as industrial machinery.

The Hexagonal Boron Nitride (hBN) particles used in Xenum lubricants are extremely small (0.25µ). These particles will neither clog filters nor coagulate, providing a smooth and reliable performance.

Used in:

Cerflon®

Cerflon® is a ceramic-reinforced fluoropolymer (PTFE) created by introducing Boron Nitride, a stronger and tougher material, into the matrix of PTFE.

This process reinforces the polymer and significantly enhances its durability and wear resistance.

Cerflon® is a patented technology.

Used in:

Carbon-graphite Technology

Carbon-graphite technology involves a dispersion of micro graphite particles in oil.

These tiny particles, only measuring 1µ in size, consist of countless hexagonal carbon crystals similar to those found in diamond. Our graphite-based motor oils provide a cost-effective alternative to our top-tier ceramic oils.

Used in: